|

|

Rib sections are placed in a jig and drilled prior to assembly

|

Vanya cleans up the splinters from drilling prior to assembly

|

|

|

Barry assembles chines with vertical rib parts. He inserts the galvanized carriage bolts and tightens with washers and nuts

|

Bill Schneider keeps Bill Hyson's drilling vertical

|

|

|

Jesse and Bill take a break

|

Boat slip where the packet boat will be exhibited

|

|

L-R: Barry Grove, Jesse Grove, Vanya Grove, Bill Schneider, Bill Hyson

Assembly work crew on July 8, 2006

|

|

|

Tim using a template for a chine.

|

Making a precision cut with the laser miter saw.

|

|

|

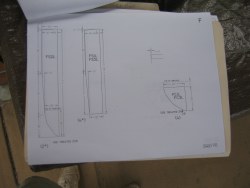

One page of the plans with specifications for a rib module.

|

Stockpiling of the rib modules.

|

|

|

Preparing another chine.

|

Rib modules and raw materials.

|

|

Precision cut chines awaiting assembly crew.

|

|

|

Anchor with Galvanized bolt and nut

|

Extender ready for additional galvanized threaded rod.

|

|

|

Tim preparing to level up the anchors to receive the packet boat.

|

Using an auger to bore holes for the threaded rods.

|

|

|

Raised anchor cradles to level the packet boat.

|

One done and four to go!

|

|

|

All five anchors now level.

|

Tim and Barry working on stringers to hold the ribs.

|

|

|

Oops. Wrong end so let's dance.

|

Wow, now we have some progress!

|

|

|

Fine tuning some modular parts of the ribs.

|

OK. Let's think this out!

|

|

|

A good day's work!

April 21, 2007

|

Saturday, April 21, 2007

Barry Grove and Bill Cooper are tightening up bolts on the ribs.

|

|

|

Barry using the ratchet wrench!

|

Tim consults with his CAD plans as Barry and Bill use the saw.

|

|

|

Barry drilling pilot holes in ribs. Tim supervising that all is plumb!

|

Assembly of the bottom and ribs near the front of the boat.

|

|

|

Assembly of ribs to the bottom frame.

|

Another good day's work. Saturday, April 21, 2007

|

|

|

Right side of boat is standing on its side to allow joining of modules and cladding of hull.

|

Barry bracing the side to keep it stable while we work on it.

|

|

|

You can see the curve of the front of the boat beginning to take shape. Note the ribs for the left side of the boat lying on the ground.

|

All the modules have now been bolted together and cladding of the bottom of the hull has begun.

|

|

|

Barry cutting plywood for the hull.

|

Bill Hyson cutting additional plywood.

|

|

|

Tim attaching a rib near the bow.

|

The shape of the right side of the packet boat near the bow. The right side is standing upright at this point to allow application of the hull.

|

|

|

Looking from the stern at the right half of the boat.

|

Curve of the bow beginning.

|

|

|

Covered up to protect from weather.

|

It takes a lot of tarp to cover this boat.

|

|

|

Hull taking shape. This is a time consuming process which requires a lot of patience.

|

Tim working out the curves needed for the bow.

|

|

|

Ah! You can begin to see the shape.

|

Adding screws to hold the hull boards in shape.

|

|

|

More work has been accomplished.

|

It is slow and tedious work to bend the boards to the compound curves required for the bow.

|

|

|

Finally, the last of the boards are in place for the right side of the hull at the bow.

|

Tim working with the grinder to smooth out some of the curves.

|

|

|

Rib assembly and fitting on the stern is now underway.

|

View from the stern of the last ribs and stern plate.

|

|

|

We will need to measure, cut, fit, and bend a lot of boards for the stern.

|

This shot gives us an idea of the length of this packet boat replica which is 69 feet!

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Applying last of 30# felt underlayment.

|

Rolling out copper for the hull cladding.

These are 100ft./100lb. rolls.

|

|

|

|

|

|

|

Tim installing the copper cladding to the hull.

|

Copper nails are used and the copper must be fitted and shaped to the compound curves of the hull.

|